Quality laser cutting and bending in reasonable turnaround time.

Since its inception, Eco Laser has provided excellent levels of customer service (particularly concerning quality and service delivery). In its effort to maintain and improve these high levels of customer service, Eco Laser has acquired various capital equipment over the years. Eco Laser currently possesses the following equipment:

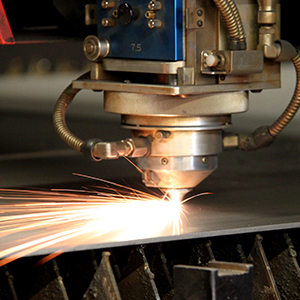

- 6KW CO2 Laser Machine (Bed size= 3000mm x 1500mm)

- 6KW Fiber Laser Machine (Bed size= 3000mm x 1500mm)

- 130 Ton Hydraulic NC press Brake

- 4KW CO2 Optic Laser Machine (Bed size= 4000mm x 2000mm)

- 4KW CO2 Optic Laser Machine (Bed size = 3000mm x 1500mm)

- 40 Ton Xpert 40/1030 Press Brake

- 3KW Fiber Laser Machine (Bed size = 3070mm x 1550mm)

Eco Laser makes use of the latest version of CNC software applicable to its industry. The software allows Eco Laser’s trained and professional staff to quickly process the wide variety of items that are laser cut and bent by the company. Eco Laser employs 20 staff members.

Eco Laser provides laser cutting and bending services to a variety of industries. Wherever there is a need for laser cutting and bending Eco Laser can assist.

About Us

Founded in 2006, Eco Laser has been providing quality laser cutting and bending services to a wide range of end users. Driven by the focus and passion of its founding member, the company has set the bench mark in delivering quality laser cut and bent items within exceptionally quick turn around times.Vision Statement

Eco Laser employs the strategy of continual improvement of its services in order to become the preferred supplier of laser cut and bent items to whichever industry requires its services. It is our vision that through exceptional service delivery and high quality, together with knowledgeable and experienced staff, laser cutting and bending may be utilised in a wide and diverse range of industries. Eco laser strives to continually lift the levels of skill and knowledge of its employees through training and guidance from senior management.

Mission Statement

Eco Laser strives to provide an exceptionally high level of quality and service to its customers. Professional and timely processing of enquiries from quotation to final product ensure that customers are completely informed regarding the status of their orders. Communication at every instance of the process ensures that all factors negatively influencing customer satisfaction levels are eliminated. An unrivalled balance between quality and speed ensures that Eco Laser remains the benchmark toward which many competitors strive.

|

|

|

|

|

|---|

Services

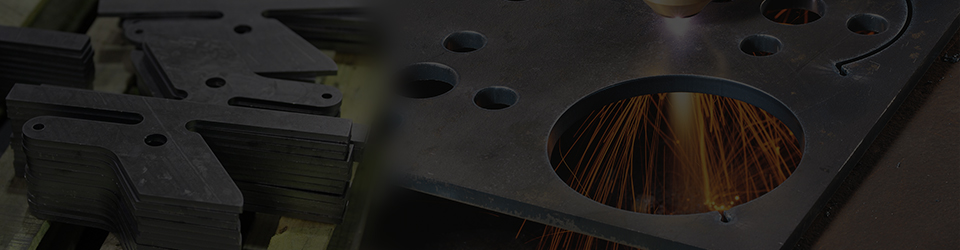

Laser Cutting

Eco Laser offers quality laser cut components from various materials on either a complete supply of both material and cutting service or on just a cutting service with the supply of material from the customer.

Various materials can be cut with the this process with minimal tolerances been given. Laser bed sizes of 3000mm x 1500mm as well as a 4000mm x 2000mm make it possible to accommodate a wide selection of sheet sizes.

Materials can be cut up to the following thicknesses

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Mild Steel up to 20mm |

Stainless Steel up to 15mm |

Aluminium up to 15mm |

Copper up to 10mm |

Brass up to 10mm |

Perspex up to 20mm |

Supawood or MDF up to 32mm |

Maximum sheet sizing: 4000mm x 2000mm

CNC Bending

CNC Bending machines are developed for high flexibility and low setup time. Our machines are able to bend single pieces as well as small batches with the same precision and efficiency as series-produced parts in an economical way.