Laser Cutting

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser most commonly through optics, and more recently through fiber optic. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Various materials can be cut with this process with minimal tolerances been given. Laser bed sizes of 3000mm x 1500mm as well as a 4000mm x 2000mm make it possible to accommodate a wide selection of sheet sizes.

Materials can be cut up to the following thicknesses

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Mild Steel up to 20mm |

Stainless Steel up to 15mm |

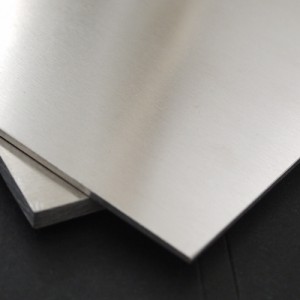

Aluminium up to 15mm |

Copper up to 10mm |

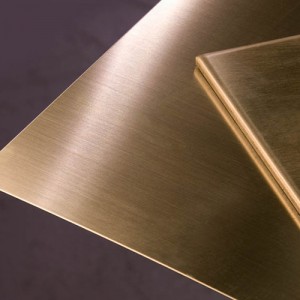

Brass up to 10mm |

Perspex up to 20mm |

Supawood or MDF up to 32mm |

Maximum sheet sizing: 4000mm x 2000mm